Following on from the project’s early development and planning phases, the second stage of our solar installation process at Innovation Nursery was centred on detailed system design.

This was a highly technical phase shaped by one guiding requirement: to create a ground-mounted solar solution that maximised on-site energy generation, supported the client’s long-term operational goals, and aligned with the innovative ethos of the site.

With a system size of 855.6 kWp, paired with 650 kW inverter capacity and 963.2 kWh battery storage, every design choice needed to ensure reliability, efficiency, and future-proofing; all while working within the unique constraints of the location.

Why an East-West Design?

To closely match Innovation Nursery’s expected energy profile, we adopted an East-West orientation across the full ground-mounted array.

An East-West solar design positions panels in two directions; half facing east, and half facing west. This means that instead of producing one big burst of power at midday like south-facing solar panels tend to do, the system can generate a steadier flow of electricity throughout the day, from early morning through to late afternoon, making the setup a better match for all-day energy use.

This approach was chosen over a traditional south-facing design for several reasons:

- Broader generation curve: a smoother, more even energy output to support the site throughout the working day.

- Better alignment with site usage: Innovation Nursery will host offices, labs, community workshops, shared spaces and on-site businesses, meaning daytime demand for electricity will be spread widely. East-West generation supports this pattern more effectively.

- Higher panel density: East-West mounting allows for tighter row spacing, increasing system capacity within the available footprint of the site.

The result is a design that prioritises long-term energy resilience and reduces reliance on the grid, by maximising the percentage of self-generated solar energy that Innovation Nursery are able to use on site.

Bifacial Solar Panels

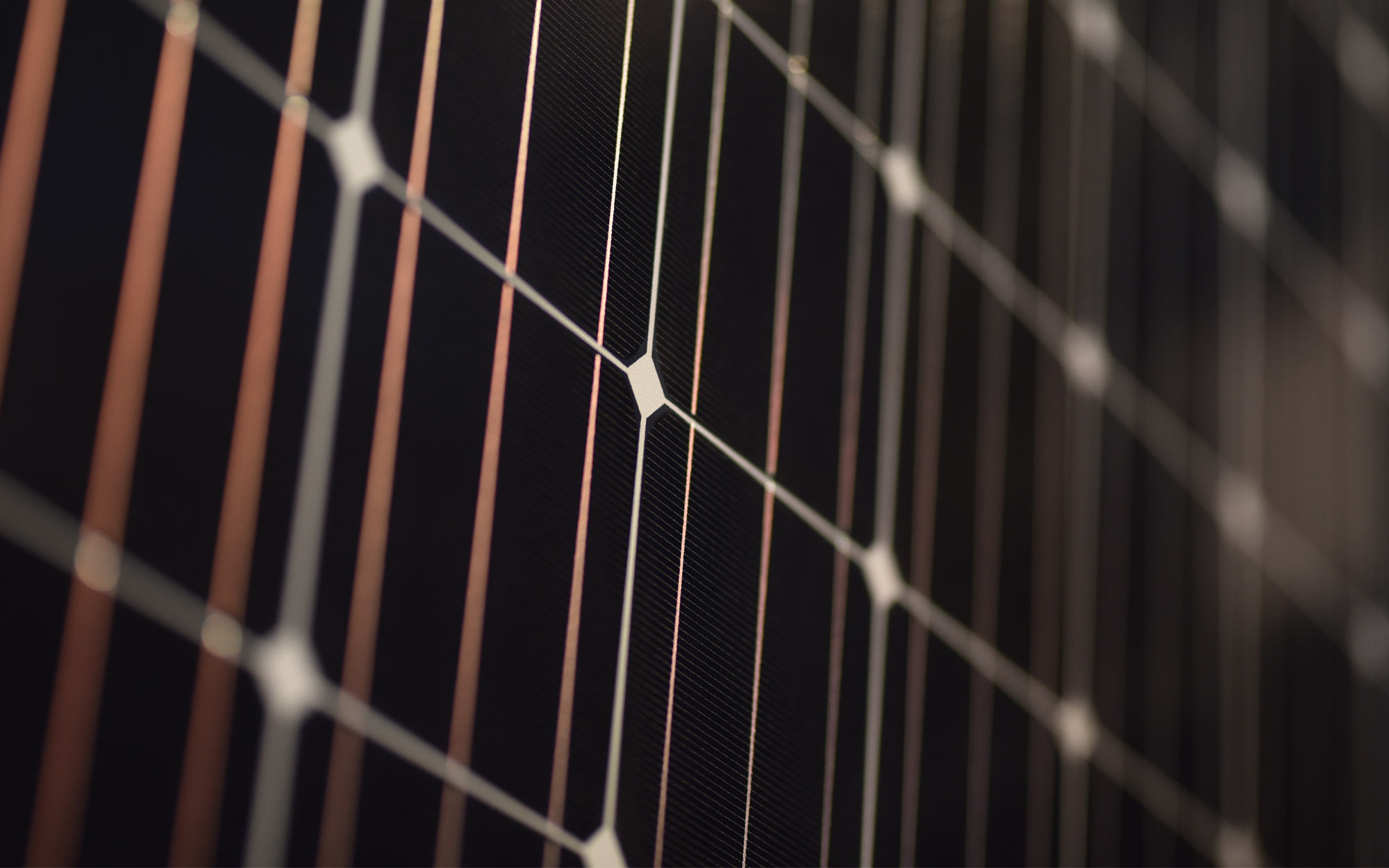

A major design decision was the use of bifacial solar panels, selected specifically to increase yield and improve the system’s overall efficiency.

Our Lead Designer Laura Greenish explains; "The panels we are using are bifacial, meaning they can generate electricity from the underside as well as the top, by capturing irradiation reflected from the ground. In the right conditions, bifacial panels can produce up to 10-20% more than a monofacial panel. While this situation will be the lower end of that, because they’re over grass rather than a white surface, it was a very deliberate decision to use bifacial panels to help maximise overall output without needing more space."

Why bifacial panels mattered for this project:

- Higher total generation without increasing land use

- Better low-light performance

- Longer lifespan due to enhanced durability

- Improved return on investment over the system’s lifetime

For an innovation-focused site expected to grow and evolve, bifacial technology was the natural fit.

The above photo shows the underside of a bifacial panel, able to capture irradiation reflected from the ground.

Engineering Around Site Constraints

The Watering Lane site brought several technical challenges, each requiring careful planning and redesign:

1. HV Infrastructure Setbacks

Buried high-voltage earthing cables run around the perimeter of the field. To meet safety and regulatory requirements, we redesigned the layout to retain a 9-metre exclusion zone, without reducing total generating capacity.

2. Minimising Inter-Array Shading

With such a large ground-mounted array, even small variations in height or alignment can cause one row to cast shade over the next, reducing how much energy the panels can generate. Our engineering team developed a stringing strategy designed to minimise shading losses, ensuring consistent output even during low-angle sunlight conditions. This included modelling morning and evening shadows and adjusting layouts accordingly.

3. Matching Framework Compatibility

We worked collaboratively with SolarPort to align our design with their existing framework system, ensuring structural stability and access for maintenance.

Technology at the Core of the System

To support the client’s goals and the scale of the project, we specified a combination of high-performance modules and robust inverter and storage technology:

- Panels: 1380 x Tongwei 620W bifacial modules

- Inverters: 2 x SunGrow 125kW units and 8 x AlphaESS 50kW units (650kW total inverter capacity)

- Battery Storage: Battery Storage: 8 x AlphaESS 120.4 kWh units (963.2 kWh total storage), mounted on Track Screws ground screws.

- Framework: SolarPort ground-mount system

This combination provides an exceptional balance of generation, controllability and resilience; all essential for a mixed-use site with ambitious sustainability goals.

What's next?

This detailed design phase laid the foundation for a solar system capable of delivering an estimated 797,862 kWh of renewable energy each year, avoiding around 157.5 tonnes of CO₂ annually. With work progressing through to early 2026, Innovation Nursery is well on its way to operating one of Cornwall’s most forward-thinking renewable energy systems, built from the ground up with design innovation at its core.

In our next post, we'll uncover the results that Innovation Nursery are able to achieve once their new system is up and running, to show what's possible with solar on this scale.

If you're interested in how solar power could revolutionise your business, find out more about our services, or get in touch to get a quote today.